| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | CNKHONG |

| Model Number : | KH-MBRP-80x120 |

| Price : | USD24/piece |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 200piece/day |

Flat MBR SS304 Rack Bio Reactor for Sewage Treatment with PVDF material 0.1um pore size

Flat Sheet Membrane

1. Introduction of MBR process and their advantages

Relying on our years of experience in this field, we are renowned as the foremost manufacturer and supplier of CNKHONG Submerged Flat Sheet Membrane Element. Our highly experienced team uses best quality PVDF for manufacturing this flat sheet. Integrated with advanced membrane fabrication technology, these membranes are designed with optimum pore sizes to get higher water flux. This CNKHONG Submerged Flat Sheet Membrane Element is widely used in wastewater treatment plants. The water produced through this MBR is much higher and gets not affected by the fluctuation of feed water.

CNKHONG Submerged Flat Sheet Membrane Element Features and Benefits

Membrane Bioreactor MBR sheet (pcs.)

| Items | Standard type | Long type |

| Model | KH-MBRP-80-PVDF | KH-MBRP-150-PVDF |

| Size (LxWxT) | 1000×490×7 | 1850×510×7 |

| Membrane effective area (m²) | 0.8 | 1.5 |

| Weight (kg) | 3 | 4.5 |

| Permeate flux [L/ (pc.d)] | 320-480 | 600-900 |

| Membrane material | PVDF | PVDF |

| Membrane pore size (μm) | 0.1 | 0.1 |

| Plate material | ABS | ABS |

| Air flow rate [L/(min.pc)] | ≥ 10 | ≥ 12 |

| pH | 2 ~ 13 | 2 ~ 13 |

| Output turbidity (NTU) | < 1.0 | < 1.0 |

| Output SS (mg/1) | ≤ 1.0 | ≤ 1.0 |

| Chemical cleaning | ~ 5,000mg/1 NaCIO | ~ 5,000mg/1 NaCIO |

MBR technology enhances wastewater treatment efficiency

Smaller occupation of Land

Brief Process of MBR technology for waste water treatment:

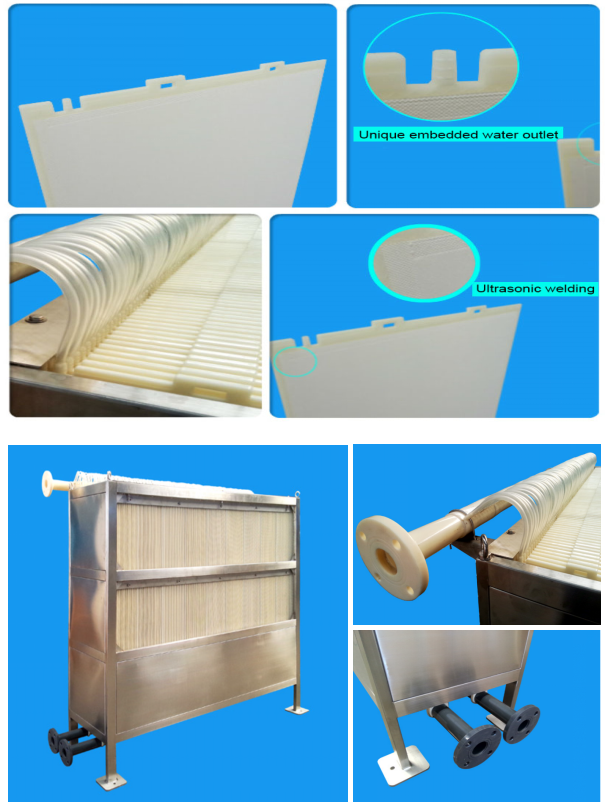

2. Description of CNKHONG Flat Sheet MBR Modules

CNKHONG Submerged Flat Sheet Membrane module configuration comprises an element block and an aeration block. The element block contains a number of membrane elements stacked at equal intervals, each of which has flat sheet membranes attached on both sides of a supporting panel. Each element is connected via a tube to a permeated water manifold. The aeration block consists of air diffusers used to supply air.

2.1 Module Features

Guaranteed high water permeability and high effluent quality

Unique membrane structure

Numerous small-diameter pores are distributed evenly throughout the membrane surface with a narrow diameter distribution. This structure ensures higher treated water quality and minimizes membrane fouling and pore clogging for consistently high water permeability.

Better membrane materials

Using PVDF (polyvinylidene fluoride) for the functional layer of the membrane and PET (polyester) non-woven fabric as the base layer allows the membrane to exhibit superior physical strength and chemical stability.

Flat sheet type membrane with modified surface nature

The membrane has a simple flat sheet configuration. This configuration and the modified membrane surface nature allow very effective cleaning by a stream of water generated upward as scouring air is diffused below it. This mechanism provides extremely stable filtration as the membrane does not allow sludge to adhere to its surface.

Advantages:

1)Water quality is good, running stability, cover an area of an area small, easy to manage

2)Membrane bioreactor device consists of hollow fiber membrane MBR and flat membrane MBR two kinds big, flat membrane compared with hollow fiber membrane, high flux, low operation pressure, strong ability to resist pollution, long operation cycle, simple cleaning, to maintain the high flux under the condition of higher sludge concentration and stable operation.

Module*(All customized models are available by online inquiry)

| Models | KH-MBRMDP150×150 | KH-MBRMDP150×160 | KH-MBRMDP150×180 | KH-MBRMDP150×200 |

| Treating Capacity | 72-90 (m3/d) | 72-96 (m3/d) | 84-108 (m3/d) | 96-120 (m3/d) |

| Quantity of membrane modules (pcs.) | 150 | 160 | 180 | 200 |

| Effective Membrane area | 225 m² | 240 m² | 270 m² | 300 m² |

| Size (LxWxH)(mm) | 2378×610×2300 | 2526×610×2300 | 2823×610×2300 | 3120×610×2300 |

| Frame material | SUS304 | SUS304 | SUS304 | SUS304 |

|